As a Submersible Pump Manufacturer, I would like to share with you the

reasons for the excessive power consumption of the slurry pump.

Slurry pumps are generally used in large-scale industrial applications. The actual products can be widely used in mining, electric power, metallurgy, coal and other industries for conveying slurry containing abrasive solid particles. Specifically used in metallurgical beneficiation plant ore slurry transportation, thermal power plant hydraulic ash removal, coal washing plant coal slurry and heavy medium transportation, etc. At the same time, it can also be used in the chemical industry. It can transport some corrosive slurries containing crystals, and it can be completed with a special material.

Submersible Pump

The common application range of slurry pump is in the mining industry, and about 80% is used in the concentrator of the mining industry. The primary ore selection conditions are relatively harsh, and the slurry pump is mainly used as the conveying medium. Therefore, in this section, the service life of the slurry pump is generally low. Faced with different ores, the abrasiveness is also different, so high chromium alloys are now used as the main slurry pump materials.

There are many kinds of materials for the flow parts of the slurry pump. The main operation process of the slurry pump is that the motor drives the impeller to rotate at a high speed to generate centrifugal force and send the material through the impeller. During operation, the flow-passing part impeller volute has to bear the erosion, wear and corrosion of materials. Therefore, the wear resistance and corrosion resistance of the flow parts of the slurry pump is an important indicator to measure the quality of the slurry pump.

The problem of excessive power consumption often occurs during the use of slurry pumps. In response to this problem, the technical staff of the slurry pump company summarized the following ten reasons:

1. The viscosity of the conveyed liquid becomes larger;

2. The speed of the slurry pump becomes higher;

3. The specific gravity of the conveyed liquid exceeds the original design value;

4. The size of the pump impeller is too large;

5. The resistance of the pipeline system exceeds or falls short of the predetermined value;

6. There is friction between rotor parts and stator parts;

7. The flow rate of the slurry pump is too large;

8. The mechanical seal exerts too much pressure on the seal seat, and the bearing is worn or damaged;

9. Slurry pump head is too low and flow is too large;

10. There is friction between rotor parts and stator parts;

In addition, such as the slurry pump balance device does not work, the uneven thermal expansion of different parts in the slurry pump, etc. are also the reasons for the excessive power consumption of the slurry pump.

Our company also has Submersible Pump on sale, welcome to contact us.

View More

View More

View More

View More

YZS Series Heavy Slurry Pump Vertical Centrifugal Pump

View More

Horizontal Centrifugal Slurry Mining Pump

View More View More

View More

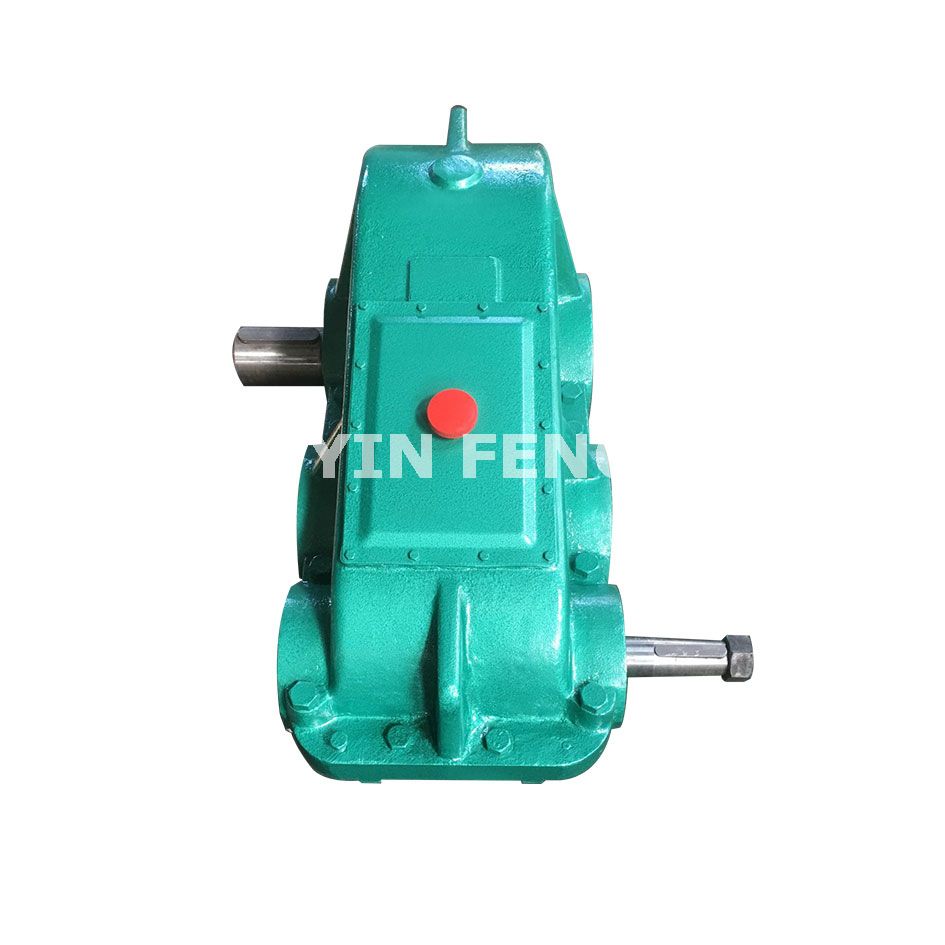

DCY Hardened Tooth Surface Bevel/Cylindrical Gear Reducer(Gearbox)

View More

TDY75 Type Oil-cooled Motorized Pulley (Motorized Drum/Drum Motor)

View More

YTH Type Build-out-gear-reducing Motorized Pulley (Motorized Drum/Drum Motor)

View More View More

View More

ZSY Hardened cylindrical Gear Reducer/Conveyor Gearbox

View More

YZ Type Oil-cooled/Oil-steeped Motorized Pulley (Motorized Drum/Drum Motor)

View More

YZW Type Build-out Motorized Pulley (Motorized Drum/Drum Motor)

View MoreCopyrights © Zibo Yinfeng Machinery Co., Ltd. All Rights Reserved | Privacy Policy